Advanced Treatments

Advanced Oxidation Process

Aquarion has its own advanced oxidation process BIOFIT.Oxyd2 which reliably removes residues in wastewater from industrial production processes that are difficult or impossible to extract using conventional biological processes.

With BIOFIT.Oxyd2 the wastewater undergoes a multistage low-pressure process that breaks down the originally non-biodegradable substances using an advanced oxidation process (AOP). BIOFIT®.Oxyd2 breaks down the polluting substances to the point where the microorganisms will metabolise the compounds, and therefore take over the remaining part of the degradation process.

A key difference from conventional methods is the specific ozonation process that Aquarion (H+E) has optimized. Here, the use of ultrasound increases the effective ozone yield, thus reducing operating costs while, at the same time, improving environmental friendliness. The result of this innovative combination of chemical and biological treatment is a highly efficient and also cost-effective process to reduce COD level and remove color. The process enables direct discharge of treated wastewater without any complications.

The basis of this technique is a combination of ozone and hydrogen peroxide that, at low pressure, targets and cracks the resistant bonds. This is known as partial oxidation. The quantity and residence time of the added ozone is precisely controlled, depending on the presence of other oxidants, e.g. hydrogen peroxide. In addition, the use of ultrasound specifically increases the effectiveness of the ozone used.

This results in fragmentation of the difficult-to-treat contaminants to the point where they can be treated and removed by simple and cost-effective microorganisms.

Wet Air Oxidation

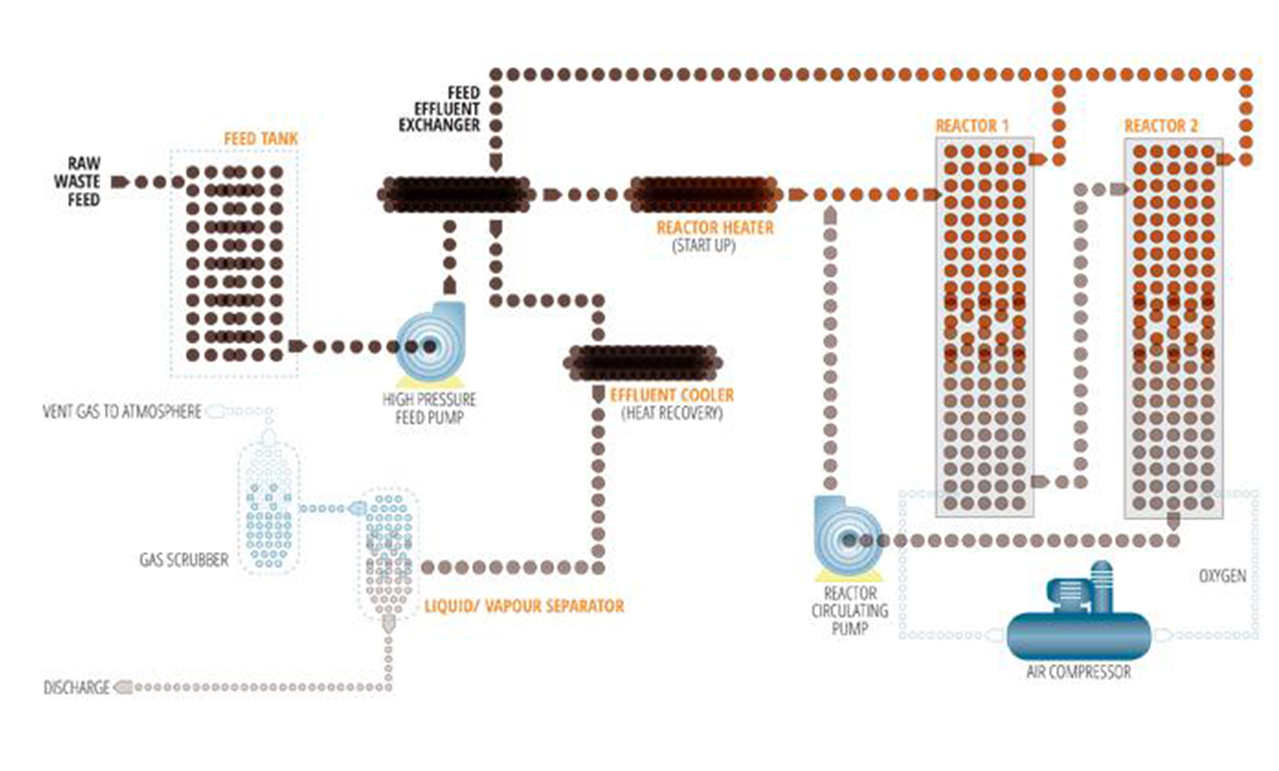

Wet Air Oxidation is a thermal treatment process. The wet oxidation operates oxidizing dissolved or suspended components in water using oxygen or other oxidizers. When the oxidizing component is air, it is termed Wet Air Oxidation.

Aquarion (Gemwater) WAO process is unique, because the reactor system is configured to promote a high degree of liquid mixing, as a perfectly stirred reactor. The result is maximum oxygen transfer from air into the liquid medium, producing improved oxidation performance at less severe operating conditions. WAO has a wide range of applications. The main applications are as follows:

• Spent caustic streams from refineries

• Ethylene production (Steam Cracking of Paraffinic Hydrocarbons)

• Gas production processes, especially during sulfur recovery units

• Soot slurry downstream hydrocracking and gasification process (syngas), in order to reduce the amount of wastewater solids requiring off-site disposal

• Petrochemical plants producing polyolefins, caprolactam, methyl methacrylate (MMA), melamine and other organic and inorganic chemicals

AQUARION (GEMWATER) TECHNOLOGY ADVANTAGES

• Air Injection Location GEMWATER injects 90% of process air into the reactors

• Heat Exchanger Orientation GEMWATER uses tube type mounted horizontally to facilitate easy maintenance and tube bundle extraction.

• Pressure Let-down GEMWATER system separates the liquid/vapor stream prior to dropping the pressure

• Reactor System GEMWATER reactor system is a CSTR type