CIRCULAR DISC MEMBRANE MODULE

MFT’s Circular-Disk-Module (CD-Module) is very well suited for the purification of highly contaminated process, waste-water Zero Liquid Discharge (ZLD) / Minimal Liquid Discharge (MLD).

One of the key objectives of environmental protection is the reduction of wastewater volumes up to complete avoidance of any wastewater volumes. By using the mft CD Module, (waste) water volumes can be massively reduced and concentrated even up to a level where a subsequent evaporation or crystallization stage makes commercial sense and pose an acceptable solution.

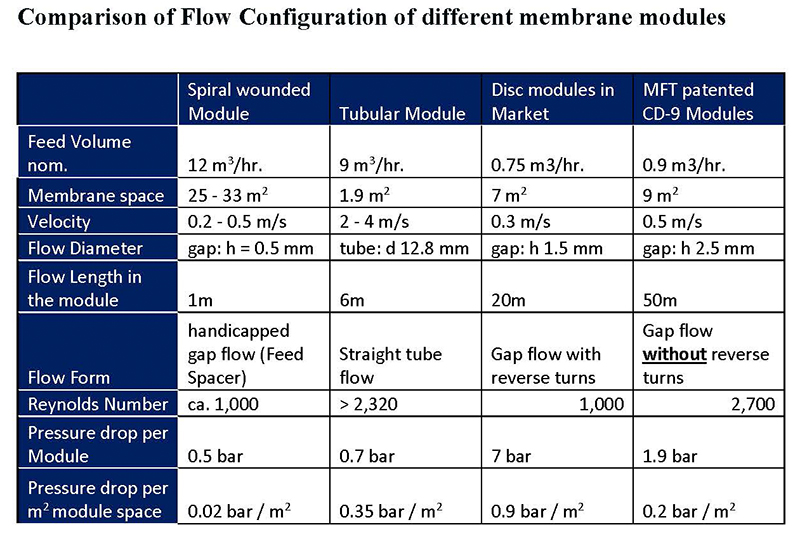

MFT uses on its own developed Nano filtration and Reverse osmosis module named circular-disc -module (cd - module) which is a major advance from the plate module technology. The cd - module is optimized in fluid dynamics and pressure compensation. Modern knowledge of the module technology is included in construction and production of the reverse osmosis and Nano filtration systems.

The concept was to build systems which allow inspection and handling in a quick and easy manner. The cd-module succeeds the aim of the cross-flow-filtration of wastewater.

The special hydraulic characteristics of the module-system ensure safe operation and high efficiency at each pressure stage.

Process Description:

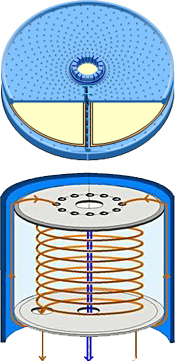

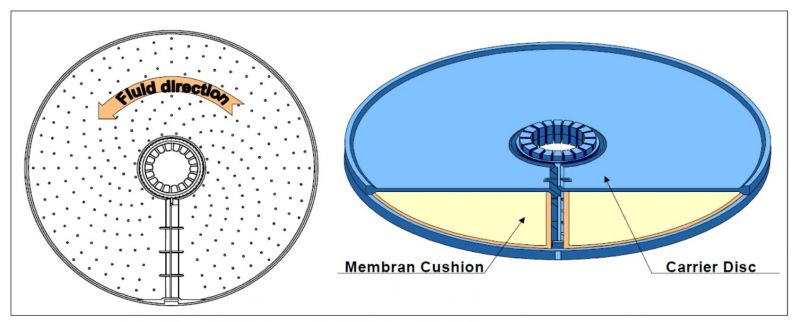

In terms of hydraulic behavior and fluid flow, the CD 140 is an optimized plate and frame module that can handle a much higher SDI-Index (Silt Density Index) than conventional membrane filtration systems and the pre-treatment can be a simple sand or cartridge based filter. The CD 140 is based upon our proprietary platform technology that has a market leading position amongst plate and frame membrane technologies. The circular flow reaches a steady and defined flow at every point of the membrane surface by leading the feed flow in a circular direction through a stack of discs with membrane cushions that are placed in between the discs.

Common Applications of CD Modules is as follows:

- Treatment and reuse of leachate from landfills and mines

- Effluent and wastewater treatment from API, formulation plant and combined effluent

from Pharmaceutical industry - Effluent treatment from textile industry and dyeing unit

- Picking and oily waste treatment in steel industry

- Metal recovery and waste recycling

- Common and combined effluent treatment and recycling

- Recycling of spend wash and bio methanation wastewater

- Tannery effluent treatment and recycling

- Reject treatment from spiral wound RO plants

- High COD/BOD wastewater treatment

- Demineralization plant waste recycling

- Hazardous chemical wastewater recycling

- Concentration of wastewater

Industries served are

- Pharmaceutical Industry

- Distillery

- Tannery

- Landfill

- Metal Industry

- & Others

Advantages of the CD – Module:

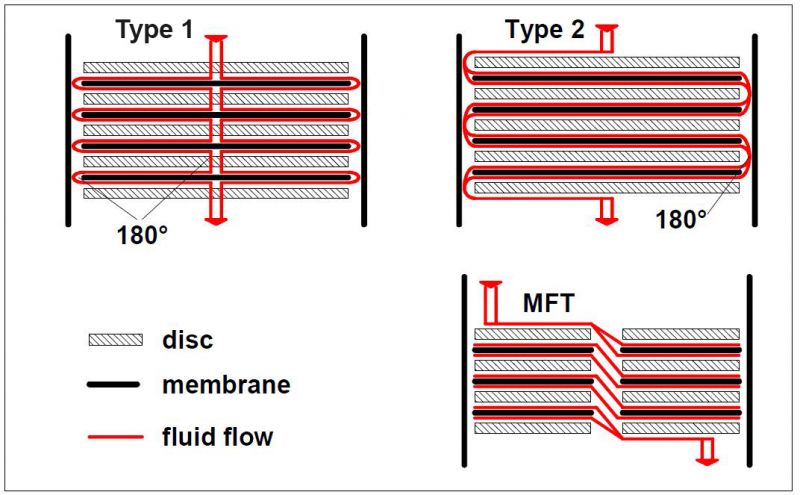

Low energy

Because of the reduced feed volume at high feed velocity and low-pressure losses in the module the power consumption is minimized.

Modular layout, simple control

The modular layout of the unit makes the equipment functional so that the unit can be enlarged at any time

Wide field of application

Because of low pressure loss and Excellent flow characteristic the CD-module can be used in Reverse-Osmosis and in Nano filtration Applications

Fail-safe equipment technology

the simple and clearly structured construction of the equipment and the use of standardized parts makes the service easy and gives a high running availability

Long lifetime of the membrane

Low mechanical stress even under high pressure & controlled shear forces of the cross flow filtration reduce the coating of the membranes & make them robust against pollution

Good cleaning behavior

Because of the open channel, technique there is an optimized cleaning hydraulic, so that the precipitation’s on the membrane surface can easily be removed and rinsed by the cleaning fluids

No use of chemicals in Water treatment

The membrane technique realizes in exemplary manner the diminution of chemicals in water treatment

High permeate recoveries

Only the disc module technique and the optimized cross flow filtration gives a high permeate recovery with all membrane materials

For Further Information, Please contact:

AQUARION AG

Zugerstrasse 76B

6340 Baar, Switzerland

Contact Person: Aditya Haridas

Tel: +49 711 7866 297

E-Mail: haridas@aquarion-group.com