Filter Technology

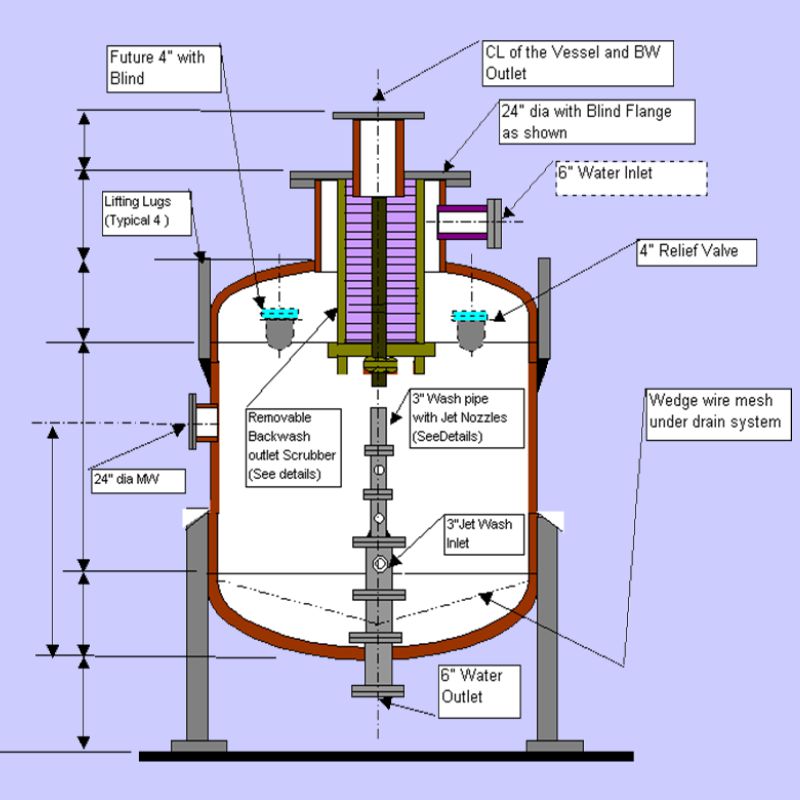

Gravel Filter / Sand Filter

Sand filter or gravel filter is a very widely used and effective technique to remove suspended solids from water. Size of the filter sand / gravel, hardness and angularity are the important characteristics to ensure effectiveness of filtration.

Sand / gravel filters finds a broad range of applications depending upon the desired treated water quality. Some of the common implementations include:

1. Pre-treatment of membrane systems

2. Wastewater treatment

3. Drinking water treatment

4. Sewage treatment etc.

During the filtration process the water to be filtered flows through a layer of gravels / sand or other appropriate media. The media holds most of the solid and the filtered water passes through the media. This is the most ancient but most common and widely used method for filtration.

When the filters are overloaded with impurities, the direction of flow is reversed to clean the filter. This process is known as backwash. After backwash the filter can be re-used for yet another operation.

Multi-media Filter

Sand filters are used to remove suspended solids from water and wastewater. Because they have one layer of filter media, sand filters remove only relatively large solids (normally in the range of 40-100 microns). The effective size of each granule of sand typically varies from 0.35mm - 1.2mm. Larger granules yield coarser filtration. Finer granules yield finer filtration. Sand filters are typically used for irrigation water, storm water, cooling water, swimming pool water.

Removing suspended solids smaller than 40 microns requires filters with either two or three layers of filter media. These are referred to as dual-media filters or multi-media filters. When sized properly and with the correct configuration of filter media, these filters can remove suspended solids as small as 5 micron. Dual and Multi-media filters are typically used for industrial process water, waste water, potable (drinking) water.

Cartridge Filter

The choice of cartridge filter depends on the application. Cartridge filters are preferable for systems with contaminations lower than 100 ppm, that is to say with contamination levels lower than 0.01% in weight.

Cartridge filter can be surface or depth-type filter: depth-type filters capture particles and contaminant through the total thickness of the medium, while in surface filters (that are usually made of thin materials like papers, woven wire, cloths) particles are blocked on the surface of the filter.

Surface filters are best if you are filtering sediment of similar-sized particles. If all particles are, for example, five micron., a pleated 5-micron filter works best because it has more surface area than other filters. Compared with pleated surface filters, depth filters have a limited surface area, but they have the advantage of depth.

It can be generally stated that if the size of filter surface is increased, higher flows are possible, the filter last longer, and the dirt holding capacity increases. Cartridge filters are normally designed disposable: this means that they have to be replaced when the filter is clogged.

Walnut Shell Filter