Zero Liquid Discharge (ZLD)

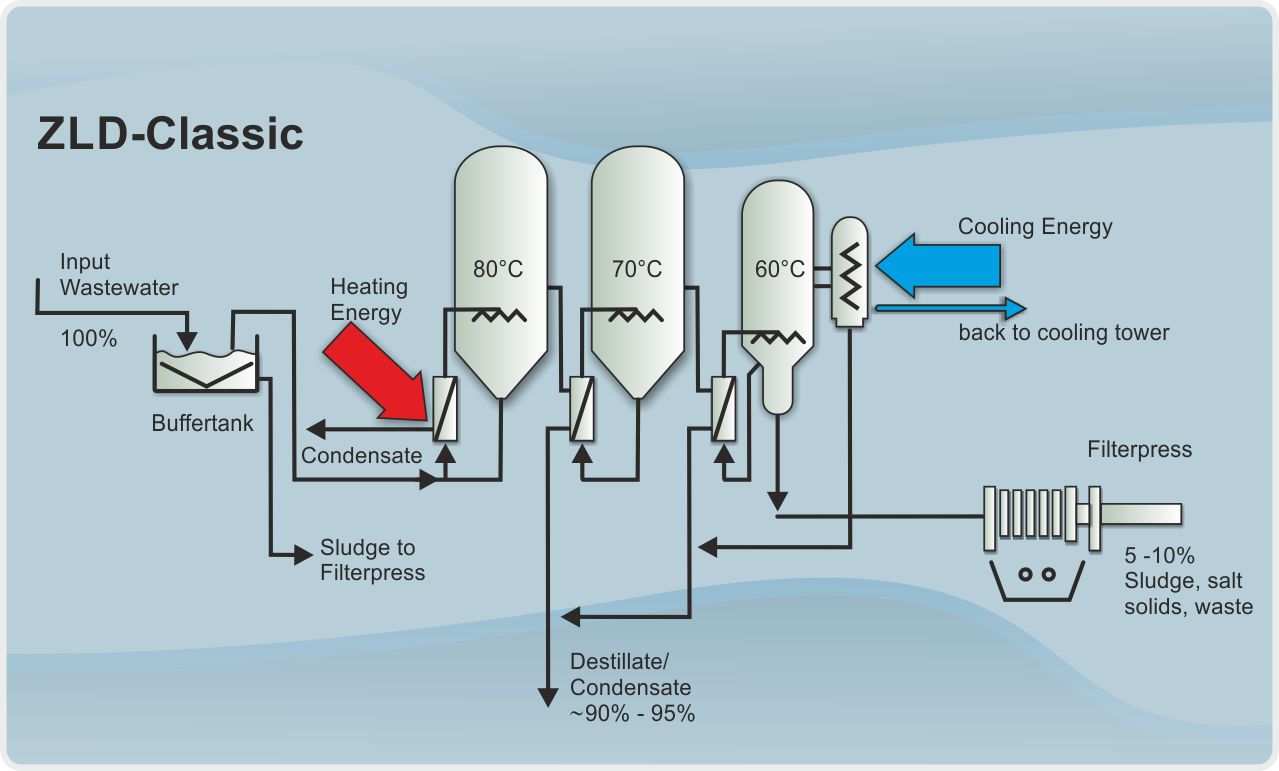

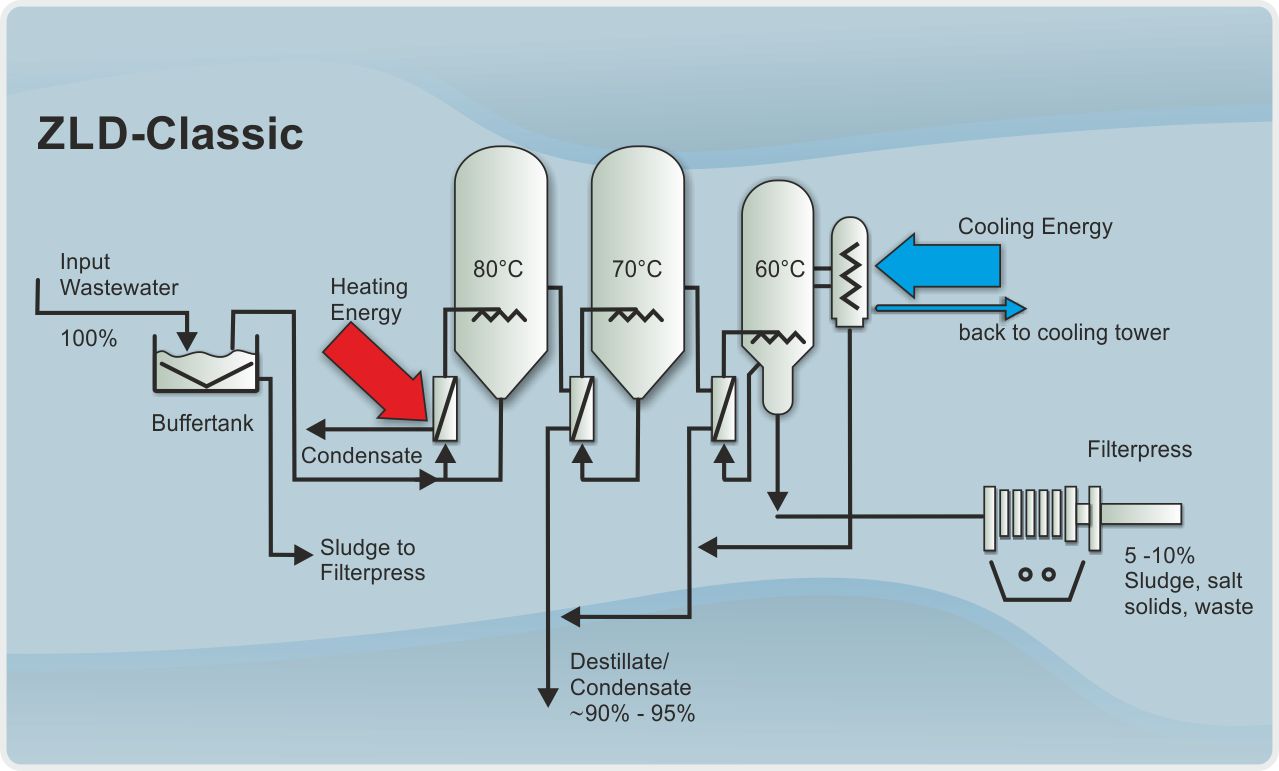

In the classic Zero Liquid Discharge water recycling and purification process, the waste-solutions obtained from a process are completely evaporated until only solid waste remains.

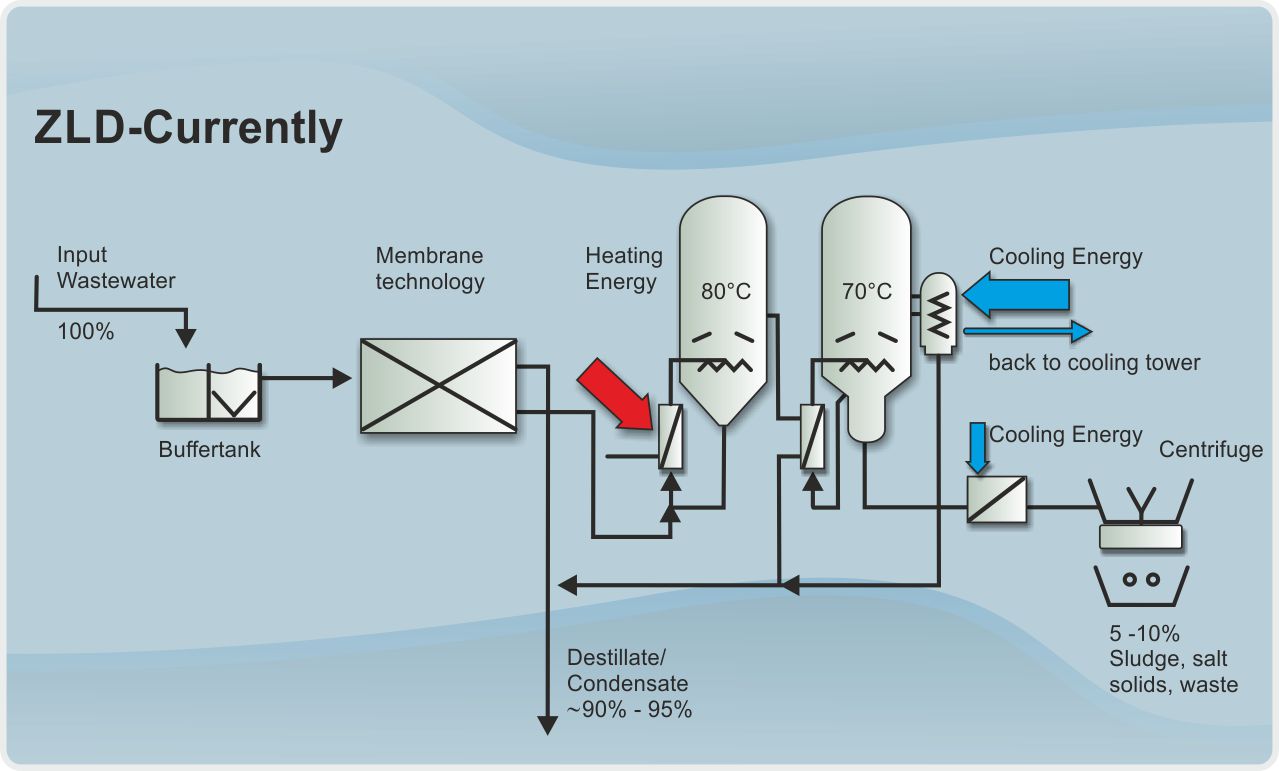

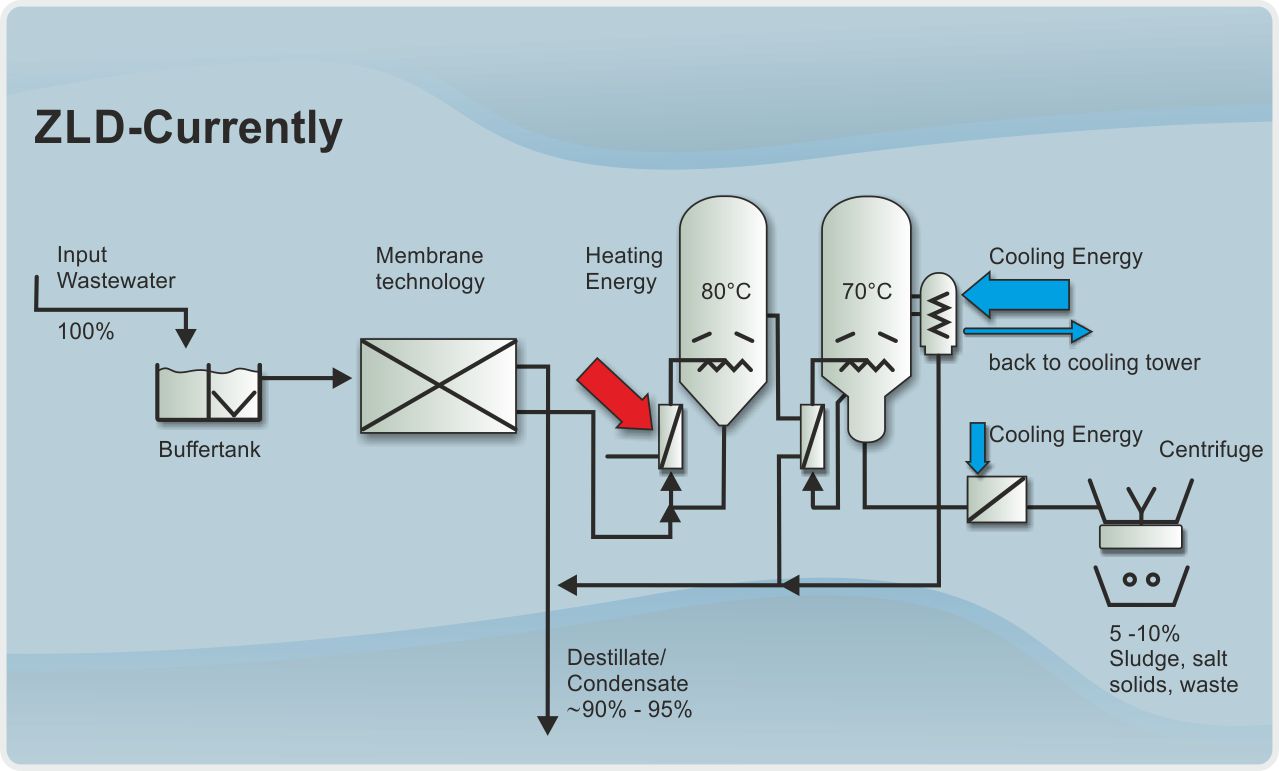

In this slightly more sophisticated technology, multiple water recycling processes are combined in order to partially replace the thermal process. Usually a portion of the liquid waste is pre-concentrated by membrane technologies. This reduction of the feed stream to the evaporator leads to lower operating and investment costs.

ZLD CLASSIC

ZLD CURRENTLY

In this slightly more sophisticated technology, multiple processes are combined in order to partially replace the thermal process. Usually a portion of the liquid waste are pre-concent-rated by membrane technologies. This reduction of the feed stream to the evaporator leads to lower operating and investment costs.

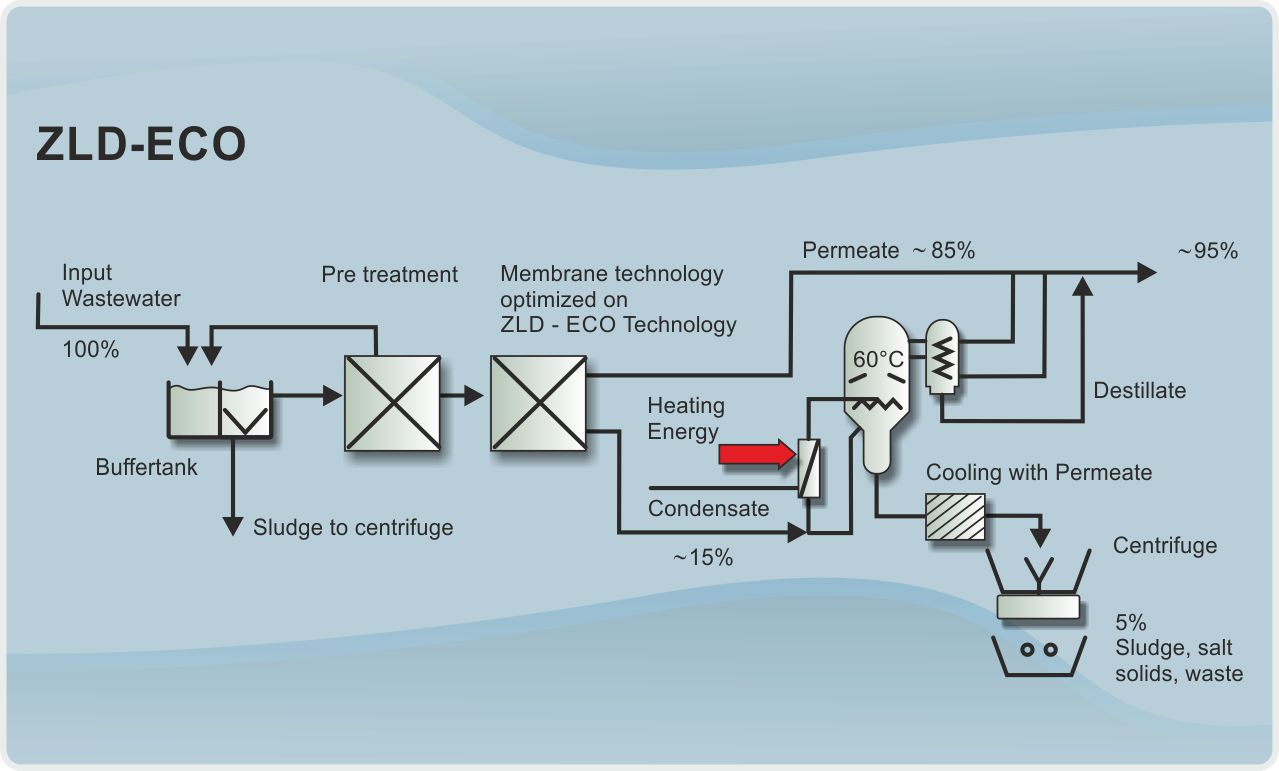

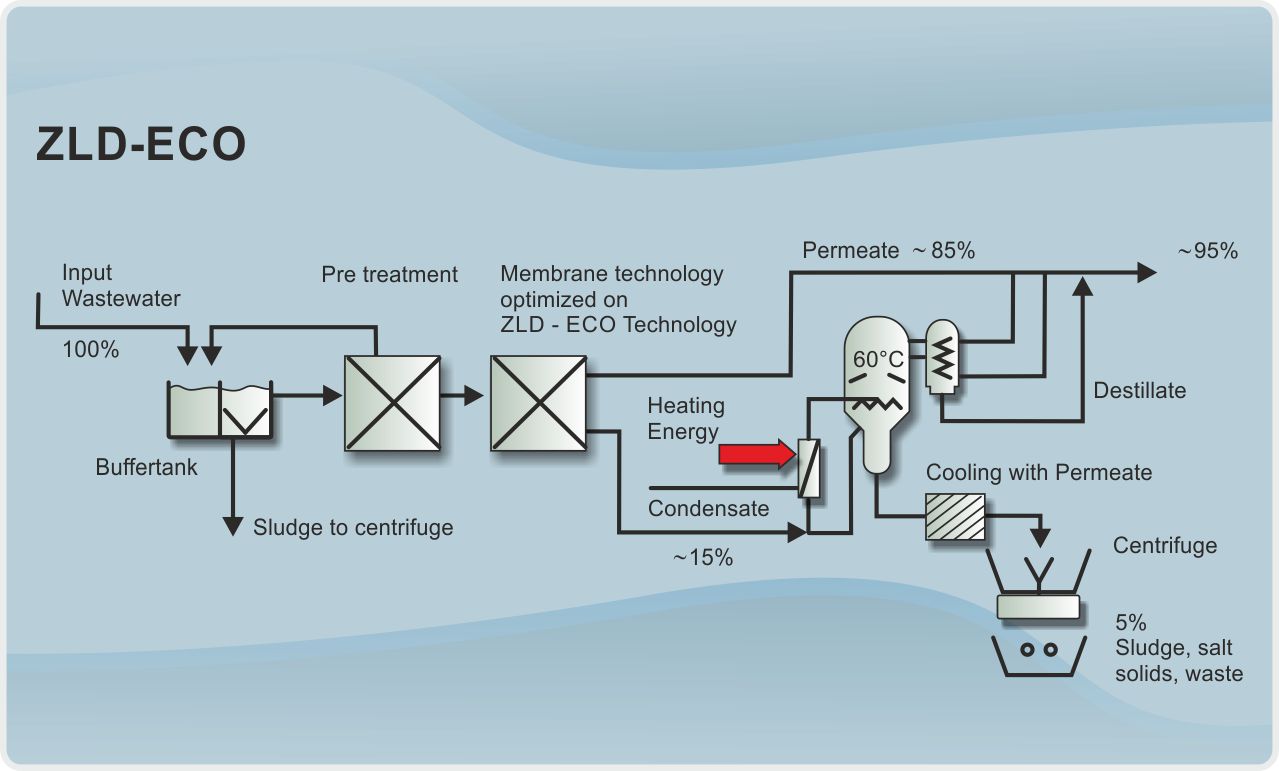

ZLD - ECO

AQUARION optimized further the ZLD process by introducing advanced pre-treatment processes that reduce thermal treatment to a minimum. This leads to lower energy and chemical consumption (cooling, heating and electrical energy) and reduced capital cost. Modular and compact designs with short production times are integrated into our holistically designed process plants.

ZLD - ECO2

Aquarion is focused on constantly improving the efficacy and cost-effectiveness of ZLD solutions. Based on the technologies used, ZLD.eco2 is one of the most reduced cost ZLD systems available today.

The ZLD.eco2 process uses a series of innovative filtration and separation technologies to reduce the subsequent evaporation of residual waste products to a minimum and lower energy requirements. The system’s modular design also reduces the plant footprint.

At the heart of the system is a new high-pressure reverse osmosis stage that utilizes Circular Disc (CD) Module technology developed by Membran Filtrations Technik (MFT), one of the Aquarion Group’s companies. ZLD.eco2 involves a pre-treatment process, which can either be chemical-physical or biological depending on the user, and an ultra-filtration stage to filter out residual organic material, followed by multi-stage membrane technology designed to concentrate non-organic waste material more densely.

After the first two reverse osmosis stages entailing pressures of up to 80 bar, the residual concentrate contains around 20% of the total waste water volume. Subsequently, this is then subjected to a third reverse osmosis stage where pressures of up 200 bar are reached. Here, MFT’s CD module is used through which water takes a circular path, thereby reducing the loss in pressure.

The high pressure warms the concentrate to approximately 70°C. This is then vaporized in the subsequent low pressure stage, which acts with the membrane technology to form a “hybrid system,” giving the concentrate a manageable consistency. The thermal energy is fed back into the system and used to increase energy efficiency. This significantly reduces the energy requirements of the entire system. The volume of waste products still present after the maximum pre-concentration produced by the high-pressure membrane technology is significantly lower than with conventional processes. As a result, the evaporation stage with ZLD.eco2 can be considerably shorter.

The Circular Disc Modules are available from MFT, and ZLD.eco2 systems are available through Hager+Elsaesser (H+E), another Aquarion Group company that has operations around the world.